Samach: Furnishing Woodworking Machines Experts

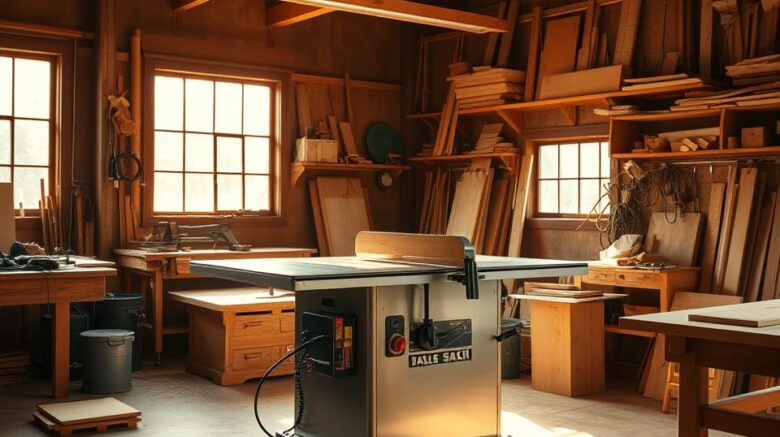

Have you ever questioned what it requires to convert unrefined substances into high-quality end products? The answer resides in exactness, creativity, and the correct tools. Samach stands at the forefront of this market, providing trusted solutions for current production needs.

Armed with extensive experience, Samach emerged as a premier name in the domain. Their state-of-the-art CNC Router are designed to deliver unmatched accuracy and productivity. Be you an expert or an enthusiast, their technology guarantees every project satisfies the highest standards.

From cutting-edge machinery to reliable support, Samach delivers all you require to succeed. Learn more regarding their groundbreaking answers by visiting www.samach.cn. This write-up will lead you through the crucial aspects of their provisions, assisting you in making knowledgeable choices regarding your projects.

Overview of Samach and Home Furnishing Machinery

Precision and innovation are the cornerstones of modern production, and Samach excels in delivering both. Drawing on extensive experience, Samach has become a trusted name in the carpentry sector, offering advanced solutions for both specialists and amateurs.

The company’s proficiency is found in merging traditional craftsmanship with modern innovations. Their woodcraft devices are designed to meet the most rigorous benchmarks of precision and effectiveness. Whether you’re working on small projects or large-scale production, Samach delivers the equipment essential for achievement.

Our Story and Samach’s Mastery

Samach’s journey began with a focus on quality and innovation. Today, they are a global leader in the woodworking machinery industry. Their panel of professionals guarantees that each item is constructed for durability, providing consistent quality and trustworthy operation.

Ranging from CNC routers to edgebanders, Samach’s catalog accommodates varied requirements. Their equipment are engineered to handle intricate operations effortlessly, establishing them as a prime option in the woodcraft market.

Online Presence and Dependable Solutions

For more information on Samach’s innovative solutions, visit www.samach.cn. Their website offers detailed insights into their product range, customer support, and global showroom locations. Samach’s commitment to excellence has made them a trusted partner for professionals worldwide.

| Characteristic | Detail |

|---|---|

| Motor Speed Range | 12,000 to 18,000 r/min |

| Operational Speed Span | 1–15 m/min |

| Top Cutting Capacity | 3,100 mm |

| Main Saw Motor Power | 5.5KW |

| Assurance Term | One Year |

Samach’s machines are backed by industry-leading warranties and ISO 9001 certification. Their global presence covers regions including Vietnam, Brazil, South Korea, making them reachable for customers around the globe.

Steering Through Woodworking Apparatus

From manual tools to advanced systems, carpentry devices provide multiple approaches for each task. Whether you are experienced or just starting out, understanding the differences between manual and automatic equipment is crucial for success.

Overview of Manual and Automatic Machinery

Manual machines, like wood lathes, require hands-on control and are ideal for smaller, detailed tasks. They deliver accuracy yet require additional time and labor. On the other hand, automatic systems, such as CNC machines, streamline production with minimal human intervention. Such systems are optimal for industrial-scale operations and sophisticated layouts.

Notable variations consist of:

- Manual systems save costs though operate at a slower pace.

- Automatic systems enhance efficiency and consistency.

- Both categories address varied demands in woodcraft operations.

Major Traits and Gains for Woodworkers

Top-notch equipment is characterized by its accuracy, user-friendliness, and capacity to process diverse substances. State-of-the-art systems secure steady performance, even on robust timber. For example, CNC machines offer unmatched accuracy, while wide belt sanders provide smooth finishes.

Gains involve:

- Enhanced output and minimized scrap.

- Augmented protective features for operators.

- Versatility in meeting shifting project needs.

The woodcraft arena consistently incorporates groundbreaking materials and advancements, thus producing machinery that is increasingly trustworthy and productive.

Buyer’s Guide to Top Woodworking Equipment for Furniture Making

Selecting the proper tools is the initial move to obtain impeccable outcomes in every task. Be it constructing cabinets or managing intricate layouts, the instruments employed can transform your output. This manual will enable you to grasp the varieties of tools offered and methods to assess their caliber for your requirements.

Comprehending Various Tool Categories

Spanning from planers to joinery devices, an extensive assortment of instruments is crafted for particular functions. Each type serves a unique purpose in the production process. For instance, surface planers excel at evening out textures, while joinery systems guarantee accurate linking of elements.

Here’s a quick breakdown of common equipment types:

- Planing Machines: Ideal for evening and refining textures.

- Assembly Devices: Secures exact and robust joints.

- CNC Machines: Perfect for complex patterns and extensive manufacturing.

Assessing Equipment Standards

Selecting high-quality machinery is crucial for consistent results. Seek characteristics such as robustness, exactness, and simple upkeep. Durable machinery improves output while cutting back on maintenance intervals and repair expenditures.

Here are key criteria to consider:

- Durability: Assess the structural integrity and constituent materials.

- Accuracy: Confirm that the device produces exact performance reliably.

- Simplicity of Upkeep: Choose machines that allow for straightforward servicing and maintenance.

Considering these aspects enables you to choose equipment that aligns with your needs and provides enduring benefits.

Crucial Components and Cutting-Edge Developments

In today’s dynamic production environment, add-ons and innovation are fundamental to improving output. Ranging from breakthrough belting methods to high-tech automation, these parts are reshaping operational dynamics. This portion delves into the revolutionary innovations defining upcoming manufacturing trends.

Creative Belting Techniques and Trim Application

Belting methods such as trailroll belts and sandbelts are transforming precision in machinery. These components secure flawless performance, particularly during edge banding procedures. Specifically, edge banding tools offer meticulous outcomes, rendering them essential for premium manufacturing.

Specialized feed systems and metal components further enhance durability. For instance, rubber alongside metal rollers is crucial for sanding operations and precise calibration. They guarantee steady operation, even under strenuous conditions.

Utilizing CNC, Turning Machines, and Additional Technologies

CNC systems and turning machines are pioneering current tech developments. CNC systems automate complex tasks, reducing manual labor and increasing precision. Lathes, on the other hand, are crucial for producing uniform pieces, enhancing both design and functionality.

Such systems combine effortlessly with other parts, ensuring optimal processing of every item. From planing machines to brushing systems, each part contributes to a streamlined production process. Ultimately, it leads to substantial enhancements in both performance and output.

By embracing these innovations, production processes become more reliable and efficient. Be it via state-of-the-art belt technologies or robotic systems, innovation relentlessly expands the horizons of capability.

Industry Shifts and Technological Breakthroughs in Carpentry Equipment

The woodcraft machinery industry is evolving substantially due to innovation and market pressures. Valued globally at USD 4.86 billion in 2023, the sector is expected to expand to USD 7.77 billion by 2032. This growth is fueled by advancements in machines and the increasing adoption of innovative materials.

Effects of Worldwide Market Changes and the COVID-19 Crisis

The coronavirus crisis briefly hindered production and sales, resulting in supply delays. Yet, the industry responded rapidly by incorporating digital strategies and modern manufacturing tech. For example, companies like SCM Group enhanced their service offerings to meet evolving customer needs.

Global market shifts have also influenced the demand for woodworking machinery. With a 40.53% market portion in 2023, Europe persists as a leader because of its commitment to eco-friendly methods. Conversely, the Asia-Pacific zone is predicted to register the fastest expansion, fueled by demographic increases and higher disposable incomes.

Innovations and Outlook for the Future

Cutting-edge developments are defining the industry’s future. CNC systems and automated machines are becoming standard, offering precision and efficiency. These innovations are particularly beneficial for large-scale production and complex projects.

Innovative materials such as Cross-Laminated Timbers (CLTs) are growing in appeal. They are both eco-friendly and capable of improving the longevity and performance of products. Consequently, producers are allocating resources to machinery capable of processing these innovative substances.

| Economic Tendency | Effect |

|---|---|

| Adoption of CNC Technology | Boosted exactness and output |

| Growth in Eco-Friendly Substances | Enhanced product durability |

| Expansion in the Asia-Pacific Area | Expanded market opportunities |

Projecting forward, the market is set for more inventive developments. The need for personalized and eco-friendly solutions from consumers will keep propelling progress. Leveraging these developments allows companies to keep pace and address the challenges of a dynamic marketplace.

Streamlining Output with Exactness and Commercial Solutions

Efficiency and accuracy are the driving forces behind modern production lines. In order to secure uniform results, the industry turns to cutting-edge machines and meticulous processes. This segment examines the ways that modern innovations can optimize workflows and enhance output quality.

Exact Milling, Trim Application, and Cabinet Fabrication

Exact milling is crucial for producing elaborate patterns and maintaining consistency in each piece. State-of-the-art CNC methods streamline the operation, cutting down inaccuracies and increasing velocity. Such machines are especially important in cabinet fabrication, where precision is paramount.

Edgebanding, another crucial process, ensures clean finishes and durability. Contemporary edge banding equipment incorporates custom feed mechanisms for steady performance. This technology is indispensable for high-quality production, especially in custom projects.

For cabinet making, precision equipment like CNC routers and joinery machines are game-changers. They handle complex designs with ease, ensuring every component fits perfectly. This degree of exactness cuts down on waste while enhancing operational output.

Approaches to Boost Manufacturing

Incorporating exact components and modern feeding mechanisms can markedly enhance production processes. These components ensure smooth operations and reduce downtime. As an illustration, mechanized feeding preserves uniform material movement, thereby increasing overall productivity.

Alternatively, utilizing modern machines for recurring assignments that not only quickens production but also secures uniform outcomes in each piece. By automating processes, manufacturers can focus on quality control and innovation.

Importance of Exactness in Ensuring Quality

Accuracy forms the bedrock of quality assurance in industry. Advanced machines ensure every cut, drill, and finish meets exact specifications. This level of accuracy is crucial for meeting high standards and customer expectations.

For example, computerized systems enable intricate coding, so that each piece is handled to perfection. This reduces errors and enhances the final product’s durability and functionality. These exact instruments reduce resource wastage, thereby cutting costs.

Adopting meticulous techniques and modern innovations enables producers to refine their production processes. This not only improves efficiency but also ensures every project meets the highest quality standards.

Concluding Reflections and Future Directions for Carpentry Mastery

Reaching peak quality in manufacturing demands proper equipment, accuracy, and an innovative mindset. In this piece, we examined how cutting-edge machines and modern strategies can reshape your tasks. Whether it’s computerized systems or dedicated equipment, the optimal tools guarantee effective and high-caliber outcomes.

Moving forward, contemplate adding superior machines to your process. Visit www.samach.cn to explore tailored solutions and expert support. Their dedication to precision and dependability renders them a reliable ally in the sector.

Welcome the freshest developments and match your project targets with state-of-the-art solutions. Concentrating on perpetual enhancement and utilizing the proper service enables exceptional outcomes. Allow creativity to propel your triumphs and boost your output to unprecedented levels.